About Colognia press

We have been producing self-adhesive labels for 27 years and we are sticking to it. During this time we have grown into one of the largest printing houses in the Czech Republic with a wide range of products.

Products

Our product portfolio includes a wide range of self-adhesive labels, flexible packaging, shrink sleeve packaging, laminate printing, and bespoke reel prints.

You can also take inspiration from our sector-divided portfolio for better orientation.

Industry solutions

We supply our products to a wide range of customers. Each industry solution has its own specifics and special needs. The experience gained over the lifetime of Colognia press is our unique contribution to the professional cooperation we enjoy with many diverse clients.

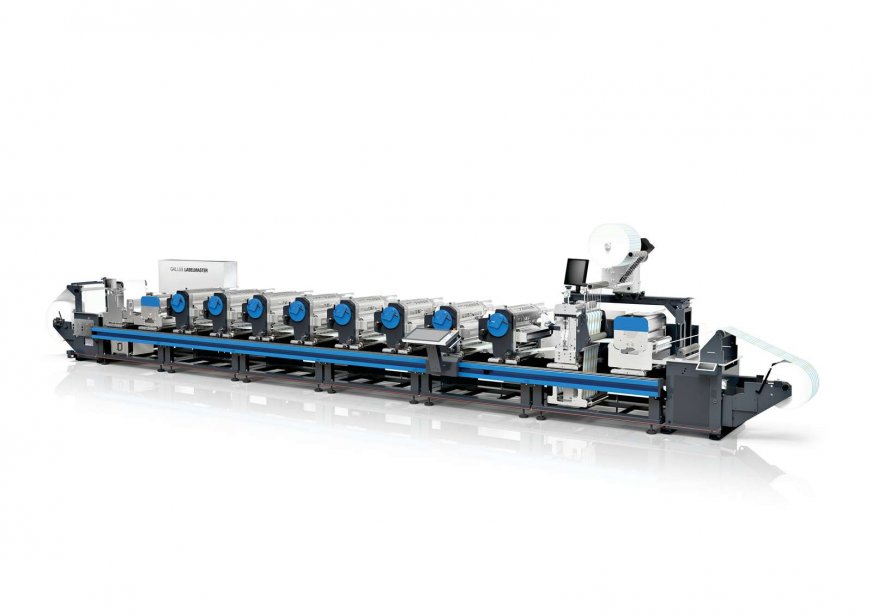

Technologies

We use the best machines in the world, operated by true masters of their craft. And it shows in our quality.